Advanced analytics techniques, how small tweaks can generate big results

According to an IndustryWeek research published from 2021, 70% of companies want to learn more about analytics, but the big question is how to get started. What if you had software tools that the process engineers could use, without the need for a data scientist and if these tools were affordable, even for small enterprises?

The example of process loop tuning

A simple form of a process controller is the thermostat which maintains the temperature of a room according to a given setpoint. It operates as a closed loop control device, trying to minimize the difference between the room temperature and the desired one.

Process optimization is key in industry and control loops are critical components. They represent a challenge for many as all processes are different. “Out of tune” loops can affect the quality of the product, the material and energy consumption, and ultimately increase the risk of recall. AI and Machine Learning can be used to improve and optimize control loops to generate big savings and reduce risks.

An advanced analytics software such as Proficy CSense can help by looking at historical data to create a model of the actual profile and recommend new settings accordingly. The model will take into account the change of parameters – such as viscosity and steam pressure in a chemical reactor – which affect the heat transfer coefficient and the flow pattern. Then the same tool can be used to monitor the evolution of the process and detect variations that the human eye cannot detect.

What is Proficy CSense in a nutshell?

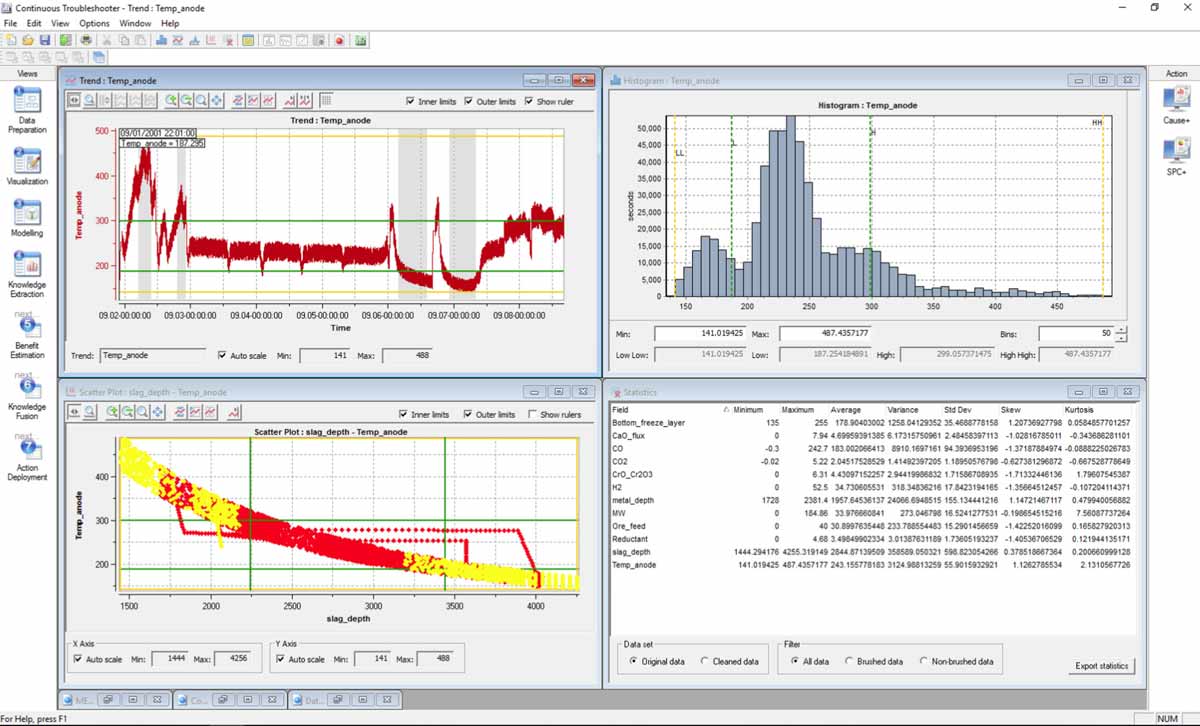

Proficy CSense makes use of a suite of components to determine and understand the causes of process deviation in industrial environments. Process engineers, quality engineers, data scientists, can analyze, monitor, predict, simulate, and optimize and control key process parameters in real time through Proficy CSense. Proficy CSense embeds patented algorithms that leverage AI and ML. It can address a wide range of problems in industry segments, such as mining, metals, food, pharmaceutical, water/wastewater, and more.

Proficy CSense includes two sets of capabilities: one for process modelling and troubleshooting, the second for online deployment and real time monitoring. Data is prepared, visualized, and rules-based, data driven process models can be constructed. Using these models, root causes of process deviations are identified, so processes can be optimized.

CASE STUDY: How a major food & beverage manufacturer optimized performance using data-driven insights

The initial goal of the project was simply to deliver savings in raw materials. With GE Digital’s software, this customer connected their machines to get all the data, model the processes to visualize what was happening. They performed in-depth analysis to understand the correlations and root causes of issues—exposing insights into what was impacting the processes and how to improve them.

Using our Proficy CSense analytics solution, they managed to stabilize the production lines and the processes and find the “profit loops” by identifying which areas of the process were causing problems.

The result was a 20% improvement in OEE, higher quality products, and an alignment of processes to where they needed to be.

Conclusion

Investing in solutions like Proficy CSense to help you optimize your processes is not expensive. Our customers can achieve a rapid payback on a small outlay.

To help you begin your journey, we are currently offering a free trial of CSense with free presentation of the software’s capabilities!

Write our sales department: sales@vix.com.pl

Written by: Bernard Cubizolles, GE Digital